Stuart Martin, EIT - Engineering Portfolio

Hello!

Thank you for visiting my web portfolio. This is a space where I showcase projects from my professional and academic career.

A bit about me..

I'm originally from Hillsboro TX, this is where, at the age of 7, I first discovered I wanted to be an engineer. Now almost two decades later, I find myself back in Texas living out my dream. I graduated from Liberty University in 2021 with a Bachelors of Science in Electrical Engineering & Minor in Mathematics.

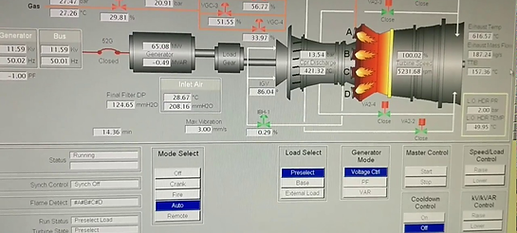

ENERCON

Gas Turbine-Generator

Situation:

The project aimed to refurbish or replace three W501F gas turbine-generator components, the WDPF turbine control system, turbine auxiliaries, and balance-of-plant systems to ensure safe and reliable operation.

Scope:

Migrate to a modern distributed control system (DCS) by evaluating the existing system, an upgrading to a Siemens DCS. Create an I/O List for field equipment, design HMI graphics, write control narrative, review vendor designs and bills of materials.

Results:

99.7% dispatch availability and is one of the flagship peaking facilities for the utility’s simple cycle generation fleet.

Solar PV Project

Situation:

Design a 150 MWdc/100MWac single-axis tracker photovoltaic (PV) facility.

Scope:

Design DC System by choosing the right PV module based on an energy yield assessment then perform a solar feasibility study, design combiner box, and then performing an power flow analysis. Choose an inverter for converting DC power from solar panels to AC power for grid integration. Followed by harmonics analysis, short circuit study, and drafting a grounding report.

Design Supervisory Control and Data Acquisition (SCADA) by ensuring inverters can communicate with central control house using fiber optics.

Results:

Designs were finalized with local township input and used to obtain use and building permits.

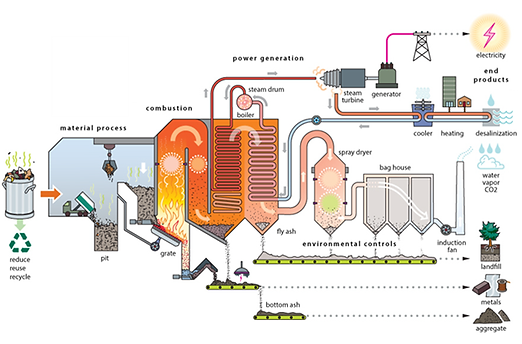

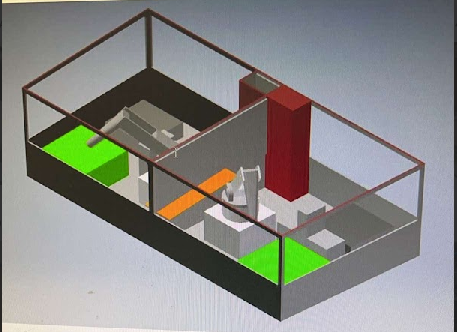

Waste-to-Energy (WTE) facility

Situation:

A waste-to-energy (WTE) facility converts municipal solid waste (MSW) into electricity or heat through combustion, gasification, or other thermal processes. The primary goal is to reduce waste volume while generating useful energy.

Scope:

Design electrical system for the facility involved the waste reception system, combustion and boiler, heat recovery for steam generator, the baghouse filters to remove particulates, the ash handling conveyor system and repository, and the grid connection from the local substation. My focus was purely the electrical aspects from such as the Steam Turbine & Generator, all the transformers, the switchgear, motor control centers, lighting, and camera system.

Results:

Designs were at 90%, with electrical team leading the design.

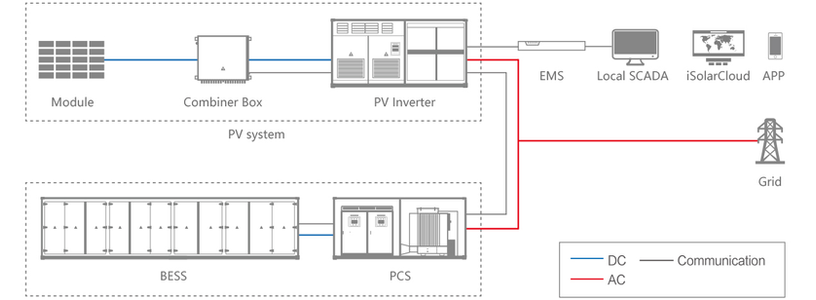

Battery Energy Storage System (BESS) Communications

Situation:

Design the communications architecture of a BESS.

Scope:

Design the fiber optic connection between the Battery Management System (BMS) which monitors voltage, temperature, and charge/discharge cycles to prevent overcharging, overheating, or faults with the Energy Management System (EMS) which optimizes charging, discharging, and grid interaction, and the Cooling & Fire Suppression Systems (hard wired) for safety with local SCADA system via Modbus.

optics.

Results:

A detailed design was supplied to the customer.

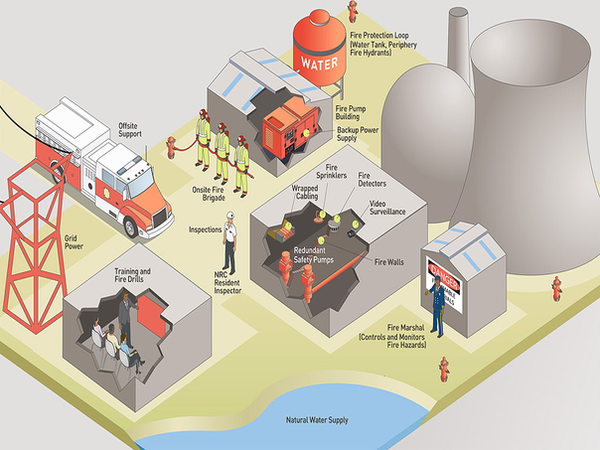

Cathodic Protection (CP) System

Situation:

Service water lines in a nuclear power plant are vital for cooling and other safety functions. Therefore, corrosion could severely impact plant operations and safety. The CP system must ensure the integrity of these lines without introducing any risks to the plant’s operations.

Scope:

Design based on soil resistivity report, which starts life cycle estimation of 20 years then with anode selection with includes resistance, anode spacing, distribution, rectifier sizing, conduit sizing, and cable schedule.

Results:

Designs were completed and the CP system was installed with quarterly testing planned.

Fire Alarm and Control Replacement

Situation:

Scope:

Results:

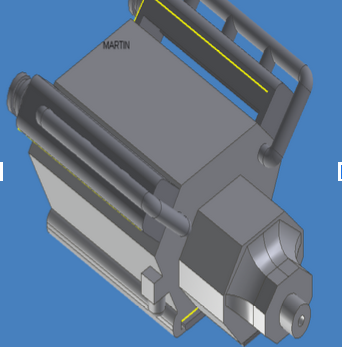

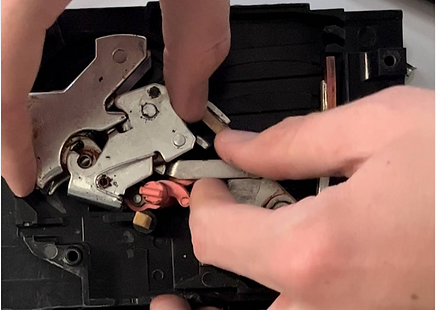

Paragon Energy Solutions

Situation:

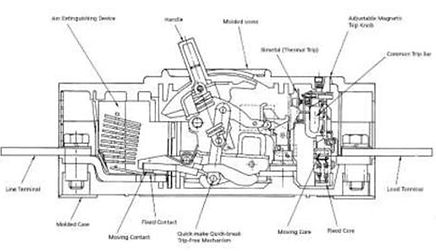

A circuit breaker (CB) failed receipt inspection for mechanical binding when actuating the handle.

Scope:

Perform failure analysis to route cause of failure:

Failure Analysis

-

Isolation of Issue:

-

I reasoned that the issue was unlikely related to components governing thermal and magnetic operation, as the problem manifested during manual operation.

-

-

Replication of Issue:

-

Attempted to replicate the issue to determine the state of actuation. This focuses on recreating the conditions under which the problem arose. To identify forces being applied by various internal components.

-

-

Dismantling and Documentation:

-

Meticulously dismantled a tested duplicate circuit breaker.

-

Documented each step to delineate the position of components as they should appear.

-

-

Comparative Analysis:

-

Compared the components of the faulty breaker to those of the duplicate.

-

Assessed the quantity, configuration upon dismantling, and examined for discrepancies.

-

Identified a unique red component as the point of divergence.

-

-

Testing with Divergence:

-

Transferred the unique component into the duplicate tested breaker. Reassembled the duplicate breaker. Then tested the duplicate breaker to verify the effect of the unique component on the assembly.

-

MAHLE Electrical & Instrumentation Engineer

Thermal Monitoring System

Situation:

A batch of piston were found to posses material fatigue at the weld line between the crown and skirt due prolonged heat exposure. The prolonged exposure was due the oven feed belt stopping after motor failure.

Scope:

Corrective action to monitor progression of pistons through the oven and alert operators of belt failure.

Deliverable:

the spokes of a gear mounted on the indirectly driven shaft makes on an inductive proximity sensor that feeds back to a PLC to record duration of pulses. The PLC has timer that resets for each pulse and adds to a counter until 1 ft of travel is accomplished. If its fails a banner light will illuminate and record the duration of the fault. The logic contains a set of bits track which parts were affected and which are not..

Temperature Recorder Upgrade

Situation:

The traditional means of measuring temperature fluctuations in an oven involved a temperature chart recorder. However, the need to monitor and produce a digital version of this data had been implemented.

Deliverable:

I developed a digital temperature monitoring solution without disrupting the existing system or compromising the integrity of the temperature controller's feedback. This was achieved by paralleling the thermocouple signal sent to both the chart recorder and the controller. Careful measures were taken to prevent any side from inadvertently influencing the controller's signal, thus preserving its integrity.

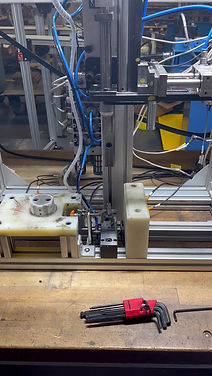

Circlip Machine

Situation:

The plant had one machine that inserts circlip to join a piston and rod. The caused losses in profitability due to overtime. The circlip aka snap ring (refer to image above) holds the connecting rod shaft to the piston.

Deliverable:

I engineered a duplicate machine with upgraded functionality to enhance adaptability, leveraging readily available materials. The machine utilizes pneumatic actuators for tooling movement, monitored by a PLC through LVDTs and proximity sensors. Its complexity stems from its ability to accommodate seven different piston and rod designs. An intuitive Human-Machine Interface (HMI) enables operators to easily select the desired piston and rod designs for assembly.

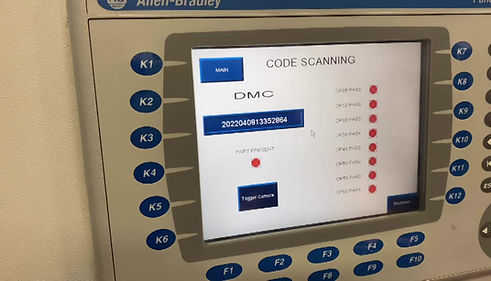

Part Tracking System

Situation:

Engine recalls due to piston malfunctions causes losses in settlements. To reduce losses lowering the number of potentially affected engines that were recalled.

Scope:

Integrate a tracking system that marks pistons and records manufactured date and production line.

Deliverable:

A time mark dot peen machine transcribes a 2D matrix containing manufactured date and line number onto each part. A Keyence SR1000 camera captures each matrix and uploads into internal database.

Automated Lines Integration

The video you see the right is the finished project. Integratsion required me to evaluate the process flow, ease of access, robot reach limits, robot posture restrictions, cable routing, and need of in cycle intervention.

Designed the interconnection between the the TimeMark dot peen machine and camera to 6-axis robot cell.

Manual Dot Peen Machine

Situation:

The automated lines system sometimes experience material failure and need to be repaired. In this event the matrix marking machine is bypassed to keep the line running.

Deliverable

I designed a manual machine that could read (left video) and write (right video) these matrices onto these rejects. DMC stands for Data Matrix Code. Since I had full autonomy when designing this machine I even created a maintenance screen to allow operators to tell the machine to run a diagnostic test on itself and determine the issue and how rectify it.

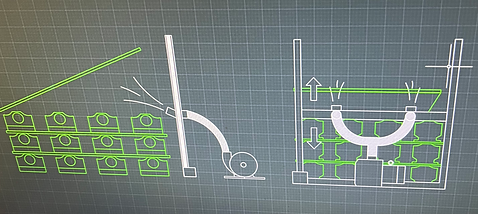

Bypass Conveyor

Situation:

The automated lines occasionally encounter processing failures necessitating operator intervention. This entails halting the robot cell for manual part removal, leading to increased cycle times.

Deliverable

I designed bypass conveyors to enable the robot to segregate process failure parts while continuing with the rest of the lot. These conveyors facilitate the transfer of rejected parts to an outdoor opening, alerting operators when full. Process sensors detect the absence of operator hands and the conveyor's reject capacity, enabling the operation. An auxiliary warning light signals the impending action to operators. This was installed and huge success.

Spacer Remover

Situation

As a new production line is being integrated, it's essential to streamline operations to minimize lead time. Currently, in the existing process, parts are stacked on a pallet with spacers between each layer. However, the robot loses 37 seconds of cycle time while moving the spacer to access the next layer.

Limitations

Parts are shipped in from another country on ballets stacked for ease of transportation and storage. The spacers vary between cardboard and plastic.

Deliverable

This concept of utilizing a blower to remove spacers included a z axis motor to lower it for each level which is controller by the cell's plc. This concept was calculated to reduce repair complexity and cycle time cost to around $2M within 2 years. to

Greif Electrical Engineering Intern

Junction Box Project

Situation:

A fire in a raceway between field components and the control room caused a loss feedback and control.

Deliverable:

Create junction box to reduce cost of reconnection. The junction box method was utilized in lieu rerunning a cable schedule since the distance was great and provided the advantage to technicians to troubleshooting without the need of engineer to connect to a PLC. This was accomplished using fused terminal blocks with LEDs to show offline indication. This involved wire tracing updating drawings in AutoCad

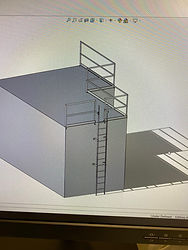

Guardrail Project

Situation:

An employee fell off this platform while repairing the HVAC unit. The court ordered the company to eliminate the hazard.

Deliverable:

Design guardrails around the platform to meet court demands. Considerations Included the OSHA requirements which dictate the heigh of 42 inches, a strength 890N at the top of the rail, openings between each horizontal rail be equal or less than 19 inches and some form of access control, which is accomplished by chaining the opening.

Framatome Engineering Intern

Job Hazard Analysis Tool

Situation

The nuclear industry is always working on eliminating hazards as workplace endures affect license renewal.

Deliverable

Develop a hazard assessment tool using questions to identify risks like electric shock and arc flash. Assess tasks, equipment, and environment, considering hazard severity, exposure duration, and access. Based on the assessment, the tool would determine necessary PPE (insulated gloves, arc flash suits, safety glasses, ear protection) and tools, displaying a list with locations after completion.

Thermographic Survey

Situation:

Medium voltage connections at the plant undergo a thermographic survey every 5 years due to thermal cycling, moisture, and vibrations, which cause materials to expand and contract, leading to loose connections in electrical equipment. Loose connections result in increased resistance as per Joule's law, leading to heating of the connections.

Deliverable:

I utilized a thermal camera to detect loose connections and communicate findings to the plant maintenance manager.

Delta Star Engineering Intern

Quote Processing Tool for Medium Voltage Transformers

Situation

Customizing medium voltage transformers extends far beyond apparent power and turns ratios, encompassing factors like cooling methods, tap changing intervals, core and coil material type, and conduit specifications. This complexity poses a significant challenge when determining pricing for customers.

Deliverable

A questionnaire would be sent to a database to calculate the price for the customer and send back an email with all the costs outlined and sent by a person using Power BI.

My Contribution

Collect material costs, and production time data for customized equipment, and consult senior engineers to determine the extent of customization for each transformer subpart.

Liberty University Electrical Engineer Student

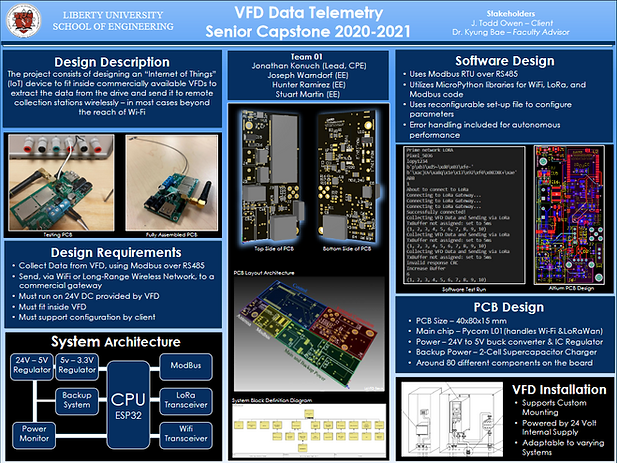

Capstone

Situation:

The university has several hundreds of motors that are controlled by a variable frequency drive. Maintenance to troubleshoot or even monitor these drives is costly.

Deliverable:

Design and create a IoT device to perform telemetry. To the right you can review considerations taken into account include design requirements, physical properties of the PCB, and stakeholders. My Contribution to the circuit was everything related to powering the unit.

Outcome:

Our capstone project was the only project to finish on time and meet all the design requirements, budget, and was physical produced and ready for mass production.

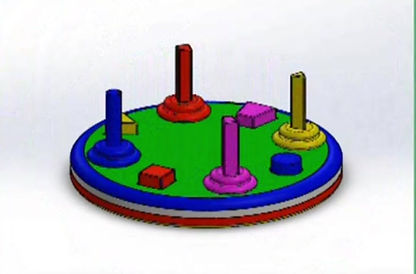

Spin-A-Stack

Situation:

Our objective is to develop a system engineering approach to project management by creating a design tailored for children.

Deliverable:

Introducing a children's toy inspired by one of my favorite toys as a kid called the "Rock-a-Stack." This is leveraging analogy reasoning, as children often grasp new concepts through familiar frames of reference, our team maintains a steadfast focus on the end user or stakeholder throughout the design process.

Firmus

Situation:

Vanuatu is a Pacific island nation located in the South Pacific Ocean, east of Australia and northeast of New Caledonia.

The general population is constantly under severe weather conditions, especially cyclones. As part of an assignment, I needed to develop a solution to combat this natural disaster.

Deliverable:

This cyclone-resistant structure features elevated foundations to allow water to pass underneath, while the roof is equipped with replaceable corrugated sheet metal to manage potential damage. Its slanted design facilitates efficient runoff of precipitation. Constructed primarily from abundant, durable ironwood native to the island, this ensures both resilience and sustainability.

Virginia Western College

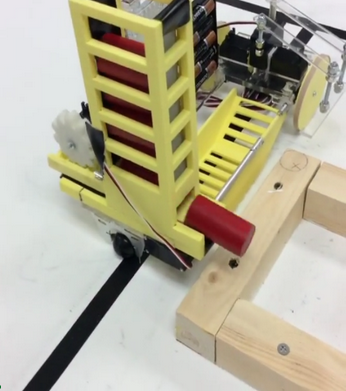

Line Following Robot Competition

Objective

Design autonomous robot to collect and dispense red cylinders around a set terrian.

Deliverable

The robot autonomously collects cylinders with an acrylic servo-propelled arm, depositing them into the basket. Using counted black marks on the ground, it navigates and determines actions at each location. At designated points, cylinders are dispensed into a wooden bin via arack and pinion method. Ultimately, the robot transports the collected cylinders in the basket to the end of the map, where they are dumped into another bin.

My Contribution

I programmed the system, which utilizes an array of infrared light sensors to gather data. These sensors emit infrared light and measure the reflected amount from the surface. When all four sensors detect a black mark utilizing sensor fusion to interpret data from each sensor, the robot logs it as a stopping event, adding it to the count. The robot then executes a programmed action based on the total count. Additionally, I designed a servo-propelled arm capable of a focused directional sweep to push cylinders into a basket. The basket's width matches the cylinder height, with a slanted bottom to maintain order, and a servo creates a dumping motion to fulfill the objective.

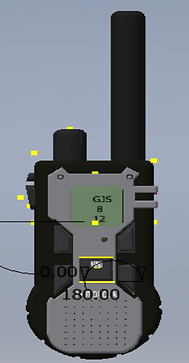

Walkie-Talkie Reverse Engineering

Objective:

The objective was to reverse engineer a item to familiarize and master Autodesk Inventor for a modeling class.

Deliverable

A fully modeled walkie talkie was to be delivered. I disassembled the Motorola walkie talkie to its irreducible sub-components without compromising the functionality. I meticulously photographed and measured each sub-component from all angles. These detailed profiles were then traced onto paper, with their dimensions recorded. Drawing these parts on paper as a reference, I then transferred the design into software. This approach was vital, leveraging my familiarity with drawing to compensate for any limitations in software proficiency.